Epilog Laser Cutter

| Epilog Laser Cutter & Engraver | |

| |

| Location | |

| In the Fabrication Lab. | |

| Classes "Laser 101" (required to use the laser cutter) |

The Epilog Laser Cutter is an Epilog 60W CO2 laser cutter and engraver located in the Fabrication Lab. It can cut sheets & boards of a variety of materials, typically paper, cardboard, wood, and some plastics. (Always refer to the #Material Compatibility List for the Laser Cutter-Engraver before cutting or engraving.) It can also engrave on glass. To engraving on cylinder-like shapes, use the rotary attachment.

Contents

Basic Information & Specs

- Laser: 60 watt CO2 laser

- Engraving area: 32″ x 20″ (812 x 508 mm) - The suggested usable area is 31" x 19" (787 mm x 483 mm).

- Engrave items up to 14.25″ (361 mm) in material height

- High-speed brushless DC servo motors

- It can be used with raster and vector type images (raster for engraving and vector for cuts)

- Weight: about 500 lbs

- Red dot pointer for visual reference for locating where the laser will fire

- Power: 110 to 240 volts auto switching, 50 or 60 Hz, single phase, 15 amp AC

- Model #: 13000 Laser System

- Serial #: 13060-1404843220

- Date of Manufacture: March 2014

Software

There's a range of software that can be used with the laser cutter. Here's a short list of typical software.

For raster images:

- Gimp (free software) Gimp Download Information

- Adobe Illustrator

- Photoshop

(An old but legally free version of Adobe Photoshop can be downloaded: Adobe Photoshop CS2 )

For vector images:

- DraftSight

- AutoCAD

- Adobe Illustrator

- Inkscape (free software) Download Options for Inkscape

The laser is used with different software as if it's a printer. Different results can be accomplished by adjusting the speed and power of the laser.

Accessories

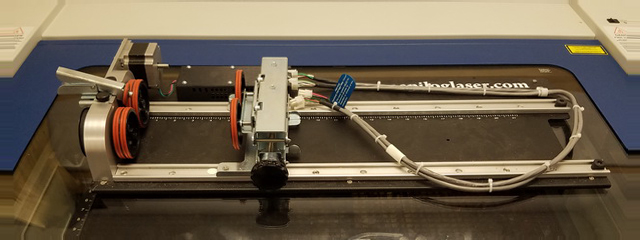

We have a "Rim-Drive Rotary Attachment" that is for use with our laser cutter.

The rotary tool is used for engraving round materials like bottles, glasses, or any other cylindrical item up to 11.25″ (286 mm) in diameter.

When plugging in the "Rim-Drive Rotary Attachment" for use, make sure the laser cutter is OFF first. Failure to do this will damage the electronics and void the warranty.

Using the Laser Cutter

In order to use the laser cutter, you must be a member of FamiLAB. You must also be certified to use the laser cutter. Becoming certified involves taking a Beginner Laser Class ("Laser 101").

Using the laser cutter is fairly simple and safe if proper usage precautions are taken. These precautions include some basic steps that are important for using the laser cutter.

Four of the first steps are the following:

- Make sure the AC is on and lower than 80ºF as the laser cutter needs to be kept cool. The laser cutter should never be used when the temperature is near, at or above 90ºF.

- Make sure the exhaust fan is on which pulls the air from the laser cutter. Use the black colored light switch to the right of the laser cutter to turn it on or off.

- Make sure the Air Assist is on next to the laser cutter.

- Make sure the laser cutter is on.

In the event that the laser doesn't work properly or is making odd sounds, contact someone on the Laser Cutter - Point of Contacts (POC) list on the wall to the right of the laser cutter (the black plaque above the computer). Also, make it known on Slack using the #laser channel. It needs to be reported so it can be fixed.

Laser 101 Class

For those interested in using the laser cutter there's a beginner laser class called "Laser 101 Class", which is held occasionally. Check the FamiLAB Calendar for when it's scheduled.

The class normally includes two parts.

- Presentation focused on safety and precautions using the laser cutter.

- Hands-on example of how to use the laser cutter. Each person will be able to use the laser cutter using Adobe Illustrator.

At the end of the class each person will be certified to use the laser cutter provided they're a FamiLAB member. Additionally, each person will be able to keep a small cut and engraved item which they made.

Material Compatibility List for the Laser Cutter-Engraver

Most of this information on material compatibility comes from Epilog's website with other information from a range of resources regarding laser engraving and cutting.

The alphabetical list below are materials that are safe or NOT safe to use on the laser cutter/engraver.

If the material isn't listed here contact someone on the "Point of Contact" list and ask.

| Material | Engrave | Cut |

|---|---|---|

| Acrylic | Yes | Yes |

| Anodized Aluminum | Yes | No |

| Bare Metals (See note #1 below) | Note #1 | No |

| Brass (See note #1 below) | Note #1 | No |

| Carbon Fiber | -->No!<-- | -->No!<-- |

| Ceramic | Yes | No |

| Cloth | Yes | Yes |

| Coated Metals | Yes | No |

| Corian | Yes | Yes |

| Cork | Yes | Yes |

| Delrin | Yes | Yes |

| Fabric | Yes | Yes |

| Fiberglass | -->No!<-- | -->No!<-- |

| Foam (Most formulations) | Yes | Yes |

| Formica (Read Note #7 Below!) | -->No!<-- | -->No!<- |

| Glass | Yes | No |

| Leather (Veg-Tanned Only) (Read Note #6 Below!) | Yes | Yes |

| Marble | Yes | No |

| Matte Board | Yes | Yes |

| MDF Board (Read Note #2 Below) | -->No!<-- | -->No!<-- |

| Melamine | Yes | Yes |

| Mother of Pearl | Yes | Yes |

| Mylar | Yes | Yes |

| Neoprene (Read Note #4 Below!) | -->No!<-- | -->No!<-- |

| Painted Metals | Yes | No |

| Paper | Yes | Yes |

| Plastic | Yes | Yes |

| Polyester | Yes | Yes |

| Polystyrene Foam (Read Note #8 Below!) | -->No!<-- | -->No!<-- |

| Pressboard | Yes | Yes |

| Printed Circuit Boards (PCBs) (Read Note #5 Below!) | -->No!<-- | -->No!<-- |

| PVC & Vinyl Based Plastics (Read Note #3 Below!) | -->No!<-- | -->No!<-- |

| Rubber (Most formulations) | Yes | Yes |

| Stainless Steel (See note #1 below) | Note #1 | No |

| Teflon (Read Note #7 Below!) | -->No!<-- | -->No!<- |

| Tile | Yes | No |

| Titanium (See note #1 below) | Note #1 | No |

| Twill | Yes | Yes |

| Wood | Yes | Yes |

| Wood Veneer | Yes | Yes |

Special Notes:

- Bare metals, Brass, Stainless Steel, Titanium: CO2 lasers will mark bare metals when coated with a metal marking solution.

- MDF Warning: MDF is typically made up of 82% wood fibre, 9% urea-formaldehyde resin glue, 8% water and 1% paraffin wax. It's the formaldehyde resin glue that's dangerous when heated and poses a considerable health risk. It can be used in the laser, but please use only in moderation.

- PVC Warning: Under NO condition should the laser be used with PVC (PolyVinyl Chloride) material. Using PVC with the laser will give off hydrogen chloride gas which can kill you. It will also damage the laser and void the warranty.

- Neoprene Warning: Under NO condition should the laser be used with Neoprene. Notice that under hazardous combustion products, the MSDS for Neoprene indicates hydrogen chloride is emitted when the material is heated.

- Printed Circuit Boards should not be used with the laser. Information from the Epilog website states that PCBs should NOT be used with the CO2 laser.

- Chrome Tanned Leather will give off toxic gases when used with a laser cutter-engraver.

| Important Note About Heating Neoprene or PVC: Neoprene and PVC produce HCl (hydrogen chloride) upon combustion or in use with the laser cutter. At room temperature, it is a colorless gas, which forms white fumes of hydrochloric acid upon contact with atmospheric humidity, the air you breath. Hydrogen chloride forms corrosive hydrochloric acid on contact with water found in body tissue, like in your your lungs. Inhalation of the fumes can cause coughing, choking, inflammation of the nose, throat, and upper respiratory tract, and in severe cases, pulmonary edema, circulatory system failure, and death. Skin contact can cause redness, pain, and severe skin burns. Hydrogen chloride may cause severe burns to the eye and permanent eye damage. Additionally, this gas will severely damage the laser cutter and void the warranty. |

Experts and References

Who to ask for help

Internal Links

External Links

- "Laser 101" class presentation (created 19 Feb 2017) (pinned in Laser channel of Slack).

- Epilog Laser website: https://www.epiloglaser.com/

- Epilog online knowledge database: http://support.epiloglaser.com/

- Epilog technical support (will email instructions on how to do the maintenance tasks): https://www.epiloglaser.com/tech-support/technical-support.htm

- Material compatibility list on Epilog Laser's website: https://www.epiloglaser.com/how-it-works/laser-material-compatibility.htm

- Wikipedia - safety information:

https://en.wikipedia.org/wiki/Medium-density_fibreboard#Safety_concerns

https://en.wikipedia.org/wiki/Hydrogen_chloride#Safety

Maintenance

| Date | Person | Notes |

|---|---|---|

| 9/8/2015 | Xomen | Full cleaning, alignment and setup after moving to new lab |

| 10/17/2015 | Xomen | Cleaned and put graphite powder on the drive shaft |

| 5/10/2016 | Xomen | Full cleaning (filter, lens, exhaust box, everything...), alignment, silicon lube on the drive shaft and bushings, blow out the filter |

| 6/14/2016 | Xomen | Minor Cleaning, alignment was pretty bad, realigned |

| 11/09/2016 | Xomen | Replaced Laser Tube, realigned |

| 2/23/2018 | Npolanosky | Replaced Laser Tube, realigned mirrors |

(I'm continually working on this page to add useful and safety information. If you must change anything please make edits with care. - Lloyd Black)