Difference between revisions of "BreepBroop"

m (→Electronics) |

(→Mechanical) |

||

| Line 15: | Line 15: | ||

===Mechanical=== | ===Mechanical=== | ||

| − | Most mechanical functions of the BreepBroop are according to the original build specifications. | + | Most mechanical functions of the BreepBroop are according to the original build specifications. A few modifications have been made: |

| − | * Using a Wade's extruder on the | + | * Using a Wade's extruder on the [http://www.thingiverse.com/thing:6278 OpenX carriage]. |

| − | + | * Hot end is a [http://www.lulzbot.com LulzBot][http://www.lulzbot.com/en/hot-ends/1-budaschnozzle.html Budaschnozzle 1.0]. | |

| − | * Hot end is a [http://www. | + | * Bed has been modified to a 1/8" thick aluminum plate, using a 110v silicone mat heater from [http://www.mcmaster.com McMaster Carr] (Part number: 35765K482), controlled by an SSR. |

| − | * Bed has been modified to a 1/8" thick | ||

===Software=== | ===Software=== | ||

Revision as of 13:44, 20 January 2012

Information

General

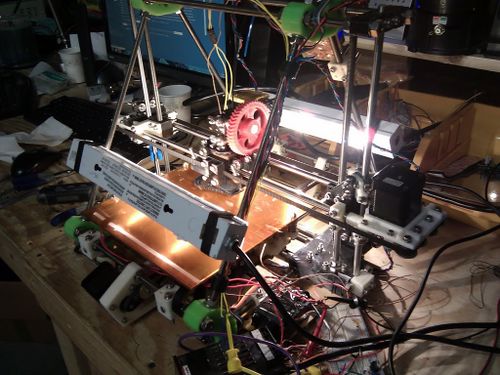

The BreepBroop (nickname) is a standard RepRap Mendel. It's the original design, and was printed during the main build rush after the Mendel came out. Chorca printed the parts on Mack's MakerBot over a period of about a month. It is all ABS aside from the frame vertexes which were purchased from the RepRap Forums, from Joshua Updyke in particular. This style of Mendel is rarely made anymore due to it's complexity. The much simpler Prusa Mendel is more commonly built, due to the large reduction of printed parts and hardware, and the simpler pulley and bearing systems used. Digitalman2112's RepRap is a Prusa.

Electronics

The BreepBroop originally used a Techzone Gen3 electronics set, which needed a good amount of touch-up and had some issues. Chorca replaced this.

- Currently using a RAMPS 1.2 board donated by Digitalman2112

- Bed heater is hooked into an Omron 15A SSR, which is controlled by the DC heater output from the RAMPS. It modulates the SSR, and detects the temperature via a thermistor kapton-taped to the bed.

- With the RAMPS, the steppers are now all drive via the Pololus onboard the RAMPS board.

- Arduino MEGA on loan from Digitalman2112

Mechanical

Most mechanical functions of the BreepBroop are according to the original build specifications. A few modifications have been made:

- Using a Wade's extruder on the OpenX carriage.

- Hot end is a LulzBotBudaschnozzle 1.0.

- Bed has been modified to a 1/8" thick aluminum plate, using a 110v silicone mat heater from McMaster Carr (Part number: 35765K482), controlled by an SSR.

Software

Chorca is currently using the following:

- Latest version of Sprinter firmware

- Host software is Pronterface, using SFACT to interface with Skeinforge

Print Status

The printer is not printing. After a total rebuild of the hot end and reassembly, we are still having major issues. It was able to successfully print a Wade's extruder gear, however, the PLA was burning and oozing out of the top of the nozzle slightly. The X axis is cracked near the belt clamp area and binding badly. The Y axis also has a lot of wobble due to the weight of the copper plate. There are no endstops so homing is a major issue. The extruder constantly strips because of the shallow hobbing and due to the fact that the thermocouples are difficult to use in getting an accurate temperature reading, it is hard to figure out what the temperature currently is.

Current Work

Electronics

The electronics system is a mess, and is very hard to operate. There have been great strides in ease of use, mainly with the RAMPS platform. This integrates all components onto one shield for the Arduino MEGA, reducing footprint and making everything a lot easier to run. The following are current plans for work:

- Replace all electronics with RAMPS board (Digitalman2112 has graciously donated a complete RAMPS kit with Pololus to my cause. I have assembled it and am borrowing an Arduino MEGA from him to use for testing)

- Swap thermocouples for thermistors to use with RAMPS (Digitalman2112 has a set of thermistors which we will attempt to use for this)

- Purchase small SSR to handle the tiny load of the heated bed, and soon the extruder heater

Mechanical

The hotend needs to be replaced and the Wade's upgraded. The X axis needs to be redone, preferably with a Prusa-style carriage to reduce weight and complexity. The following are current plans for work:

- Replace hot end with LulzBot pre-built Budaschnozzle

- Replace X carriage with Prusa-style carriage

- Swap smooth rods for smoother rods on X axis and use oil-impregnated bushings to ride along the rails for greater accuracy

- Replace copper bed with aluminum bed to lower stress on Y axis and prevent wobble

- Fix hobbed bolt on Wade's extruder (Run tap on bolt for longer, cut deeper grooves to get better traction on filament)

- Replace herringbone gears with original gears OR print new extruder such as Greg's Accessible Extruder and use it instead