Difference between revisions of "Enco 100-1588 Manual Knee Mill"

(Adds category. Minor reformatting.) |

m (Fixes npolanosky spelling.) |

||

| Line 12: | Line 12: | ||

* Spindle Speed (low range): 70 to 250 RPM. | * Spindle Speed (low range): 70 to 250 RPM. | ||

* Spindle Taper: R8 | * Spindle Taper: R8 | ||

| − | |||

| − | |||

== Detailed Pictures == | == Detailed Pictures == | ||

| Line 34: | Line 32: | ||

=== Experts === | === Experts === | ||

| − | * [[User: | + | * [[User:Npolanosky]] |

=== External Links === | === External Links === | ||

| − | * [https://www3.nd.edu/~hessmach/index_files/Enco%20Mill%20Manual100-1525.pdf Manual]. ( | + | * [https://www3.nd.edu/~hessmach/index_files/Enco%20Mill%20Manual100-1525.pdf Manual]. (Dead link; see Talk.) |

[[Category:Metal Shop]] | [[Category:Metal Shop]] | ||

Latest revision as of 21:36, 28 April 2019

The Enco 100-1588 Manual Knee Mill is a clone of a Bridgeport milling machine. It is located in the Metal Shop. This machine is capable of precision drilling, milling, and boring of metals and engineering plastics. The head is mounted on the ram by joints that allow it to swivel in two directions. The ram can slide back and forth on the turret, which can swivel on the column. The table sits on the knee, and it can move horizontally in the X and Y axes. The knee rides up and down the column (one form of Z-axis movement), and the head contains a quill in which the spindle can slide up and down (another form of Z-axis movement or, when the head is swiveled, an additional axis).

Training is required.

Contents

Basic Specifications

- X Travel: 36" (915mm)

- Y Travel: 12" (305mm)

- Z Travel: 16" (405mm)

- Quill Travel: 5" (125mm)

- Spindle Speed (high range): 600 to 1200 RPM. (Spec'd to 4200 max, but we have a derpy belt system that needs repairs.)

- Spindle Speed (low range): 70 to 250 RPM.

- Spindle Taper: R8

Detailed Pictures

Our Mill and Accessories

5C Rotary Indexer

Fitted with a traveling spindle and collar, the 5-C Spin Index is unmatched for forming, grinding, and inspecting end mills and other fluted cutting tools as well as machining parts at varying angles. This spin index accepts 5-C collets up to 1-1/8" capacity and features a 36 hole indexing plate with 10 vernier holes for indexing to 1 degree. Locking spindle is hardened and ground and has 2-1/16" of travel.

Coolant

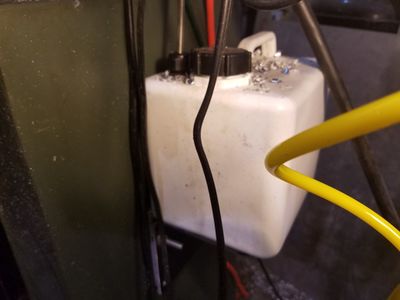

The mill uses mist coolant (currently Kool Mist #77 is in the tank) to help evacuate chips and lubricate the cutting tools. The coolant comes out of a nozzle which is attached underneath the head. To turn on the coolant, make sure the air compressor is on and pull the black knob *outwards*. To adjust the flow of coolant, rotate the nozzle. Less is more! Make sure there is a fine mist, rather than a flood of liquid. Point towards the location of the cut and enjoy long-lasting tools with an excellent surface finish.

To refill coolant if it is low, mix the Kool Mist #77 concentrate (Location: blue liquid in water bottle on shelves to the right of mill) to a 30:1 ratio with water and fill coolant tank.

Experts and References

Experts

External Links

- Manual. (Dead link; see Talk.)