Difference between revisions of "Kiln"

(→Temperature Controller) |

(→Temperature Controller) |

||

| Line 46: | Line 46: | ||

Terminals 1, 5, 11, and 12 have nothing connected to them. | Terminals 1, 5, 11, and 12 have nothing connected to them. | ||

| − | Terminals 9 and 10 are wired to the 240V plug, in parallel with the heating elements. | + | Terminals 9 and 10 are wired to the 240V plug, in parallel with the heating element/solid state relay circuit. |

| + | |||

| + | Terminal 3 and 4 are connected to the ridiculously long wires of the thermocouple. I'm not sure if trimming them back would mess with the calibration or not. Or even if the thing is calibrated. Homework for some intrepid individual. | ||

| + | |||

| + | Terminals 6 and 8 go to the solid state relay. It is a handsome fellow, fluent in three languages (if you count "love"). | ||

| + | |||

| + | [[File:feeltheberme.jpg]] | ||

| + | |||

| + | The display on the temperature controller shows the current temperature measured at the thermocouple in degrees Celsius (in red) and the target temperature (in green). | ||

| + | |||

| + | [[File:inkbird_display.jpg]] | ||

| + | |||

| + | If the current temperature is less than the target temperature, the controller will activate the solid state relay, which connects the heating elements to power. | ||

| + | |||

| + | If you wish to change the target temperature '''CLEAR YOUR MOFRIGGIN CALENDER BOYS AND GIRLS CAUSE WE GOING ON AN ADVENTURE!''' Holy crap! I mean, ok, let me explain: the temperature readout is 4 digits. Usually 3 big boys and a tenths place after that all-important decimal place. Have I told you how important that decimal place is? No? It's because it can eat a bag of rusty potatoes and go die. Because some damn Chinese nerd, no doubt on orders from the f-the-usa bureau, decided that we needed to spend TEN TIMES the time it would take to ''Actually'', before that rant starts world war three, I'd like somebody to push the left arrow and see if we can change the temperature in a quantity greater than tenths of a degree. I'll be very happy, because it takes way too long to change temperatures as is. | ||

| + | |||

| + | But that's how you do it. | ||

| + | |||

| + | You'll notice there are indicators for "AL1" "AL2" "OUT" and "RUN" on the FACE of the display as well. I think I read somewhere this thing can be programmed and AL stands for Alarm. "OUT" seems to come on when the elements are on, maybe it means out of the specified temperature range? I would really like there to be a manual for this somewhere. | ||

== Element Failure Theory == | == Element Failure Theory == | ||

Revision as of 23:39, 29 January 2018

We have one and a half kilns.

The whole kiln is an Evenheat 6320-XL.

Kiln Manual: http://www.evenheat-kiln.com/pdf/manual-c-6320xl.pdf

Kiln Setter Manual: http://www.evenheat-kiln.com/pdf/manual-c-kiln-sitter-with-limit-timer.pdf

A-66B

The half is a Paragon A-A6-B stacked on top of a Paragon A-66-B, and it's terrible and broken. (it's fixed!-ish Jury still out on terrible. No more a-a6-b?)

Paragon's Instructions on measuring heating element resistance. https://www.youtube.com/watch?v=nrUIdOTOJ48

I don't know what our kiln's resistance *should* be, but the A-A6-B's coil read at 34.6Ω

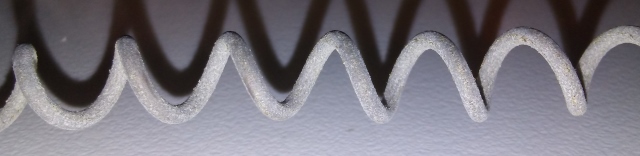

Late December 2017, the lab received 2 factory-new elements from Paragon Industries for the A-66B. They each have a resistance of approximately 7.5Ω The values were hand-written on the packaging the elements arrived in, presumably after a factory test. Mechalich confirmed this is about right with a sparkfun multimeter, with one element reading about 0.3Ω less.

We gotta do this: https://www.youtube.com/watch?v=7RPO1S4R5ag (Done!)

http://www.paragonweb.com/files/wiringdiagrams/A66WD.pdf

http://www.paragonweb.com/files/manuals/IM-5_A_&_B_Inst_&_Service_Manual_July2010.pdf

http://www.paragonweb.com/files/manuals/A_Series_Electrical.pdf

Axner's Supply[1] is 25 minutes from lab and will be a good local resource for supplies and repairs.

Temperature Controller

The A-66B kiln uses this temperature controller:

Inkbird ITC-100VH Terminals 1, 5, 11, and 12 have nothing connected to them.

Terminals 9 and 10 are wired to the 240V plug, in parallel with the heating element/solid state relay circuit.

Terminal 3 and 4 are connected to the ridiculously long wires of the thermocouple. I'm not sure if trimming them back would mess with the calibration or not. Or even if the thing is calibrated. Homework for some intrepid individual.

Terminals 6 and 8 go to the solid state relay. It is a handsome fellow, fluent in three languages (if you count "love").

The display on the temperature controller shows the current temperature measured at the thermocouple in degrees Celsius (in red) and the target temperature (in green).

If the current temperature is less than the target temperature, the controller will activate the solid state relay, which connects the heating elements to power.

If you wish to change the target temperature CLEAR YOUR MOFRIGGIN CALENDER BOYS AND GIRLS CAUSE WE GOING ON AN ADVENTURE! Holy crap! I mean, ok, let me explain: the temperature readout is 4 digits. Usually 3 big boys and a tenths place after that all-important decimal place. Have I told you how important that decimal place is? No? It's because it can eat a bag of rusty potatoes and go die. Because some damn Chinese nerd, no doubt on orders from the f-the-usa bureau, decided that we needed to spend TEN TIMES the time it would take to Actually, before that rant starts world war three, I'd like somebody to push the left arrow and see if we can change the temperature in a quantity greater than tenths of a degree. I'll be very happy, because it takes way too long to change temperatures as is.

But that's how you do it.

You'll notice there are indicators for "AL1" "AL2" "OUT" and "RUN" on the FACE of the display as well. I think I read somewhere this thing can be programmed and AL stands for Alarm. "OUT" seems to come on when the elements are on, maybe it means out of the specified temperature range? I would really like there to be a manual for this somewhere.

Element Failure Theory

Billions of years ago, microorganisms known as stromatolites evolved a defense mechanism allowing them to toxify the atmospheres of planets with a deadly poison: Oxygen. Where they thrived, other organisms were killed by elevated concentrations of this gas. While this new atmosphere allowed radical new metabolisms to exist, it sucks mad butt for exposed metallic surfaces which promptly oxidize. Beautiful, lustrous metallic crystals are oxidized to brittle, dull powders. Metal didn't even do anything wrong! Why stromatolites gotta be haters? So we grab Ed's knives, jump into the ocean, and carve these little buggers into extinction? Too late. Their photosynthetic legacy has doomed metal to be hidden beneath protective coatings. An unfortunate, added expense of using engineered materials on a biologically active planet.

Kiln elements begin to develop an oxide coating as soon as they are exposed to air. This oxidation reaction takes place rapidly at elevated temperatures, such as those found at normal operating temperatures inside a kiln. This oxide coating thickens with use and reduces the exposed surface area to our deadly, deadly atmosphere, slowing the process. With the continued thermal expansion and contraction of the metallic elements, this coating slowly flakes off, exposing more and more metal. This runaway reaction causes the resistance in the elements to increase with use and temperature.

Ultimately, a corroded section of the heating element fails. Mechalich observed if a section breaks while the element is hot, the hot metal begins thermionic emission creating a plasma that vaporizes the metal and briefly allows current to flow through the gap, melting the element further and leaving a glassy coating on the insulating firebrick until the plasma arc extinguishes. This phenomenon can be heard as a 60Hz buzz at the moment of failure.

Corners create hot-spots in the kiln where thermal failures happen first.

Mechanical failure of a corroded element is also possible. The oxidation of the elements leaves them brittle. Like a pretzel stick, it probably won't break under its own weight, but any attempt to bend it will result in a bad time. Only while the elements are red hot do they soften enough to be manipulated back into their grooves.