Difference between revisions of "3D Printing"

LloydBlack (talk | contribs) |

|||

| (19 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

| − | {{ | + | {{Merge|3D Printers}} |

| + | ---- | ||

| − | + | '''[[Approved_Filaments|Approved Lab Printer Filaments]]''' <--- Click here if you need to know which filament to buy for use on FamiLAB printers! | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | == 3D Editing Software == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | = | ||

[https://www.tinkercad.com/ - TinkerCad] | [https://www.tinkercad.com/ - TinkerCad] | ||

| Line 46: | Line 29: | ||

[https://pixologic.com/ - Zbrush] | [https://pixologic.com/ - Zbrush] | ||

| + | == 3D Slicing Software == | ||

| + | [https://ultimaker.com/en/products/cura-software - Cura] | ||

| + | |||

| + | [http://slic3r.org/ - Slic3r] | ||

| + | |||

| + | [http://www.kisslicer.com/ - KissSlicer] | ||

| + | |||

| + | [https://www.simplify3d.com/ -Simplify3d] We have a lab license and this is the primary software used for our printers. Can be found on the right-hand FabLab printer. | ||

| + | |||

| + | == Prepping Model for Slicing == | ||

| + | Recommended File Type: OBJ or STL | ||

| + | |||

| + | Avoid 5+ sided faces | ||

| + | |||

| + | No [https://en.wikipedia.org/wiki/Manifold manifold] geometry or Lamina faces (faces sharing all edges) | ||

| − | + | Check scale and orientation! Z-up & Millimeters | |

| − | |||

| − | + | == Slice Model to Print == | |

| + | There are many model slicing softwares available. Each one gives you gCode but not all give you the same amount of control over your print settings. 3D Printing can be temperamental. From filament varieties, bed adhesion, and environmental changes many factors will effect the quality of your print. The widely preferred slicer at Familab is Simplify3d, which was crowd-funded in February 2016. '''Here is a [https://www.simplify3d.com/wp-content/uploads/2015/06/S3D-Quick-Start-Guide-v3.pdf quick start guide] from Simplify3d!''' | ||

| − | 3) | + | == The DeltaMaker == |

| + | [[File:01 DeltaMaker.JPG|400px|thumb|left|Our Deltamaker]] | ||

| + | |||

| + | 1) Prep & slice 3D model. | ||

| + | |||

| + | 2) Turn on printer switch on back of machine. | ||

| + | |||

| + | 3) [[https://familab.org/wiki/File:03_Login.PNG Login to Octoprint]] on lab network. | ||

URL: deltamaker.familab.org | URL: deltamaker.familab.org | ||

Username: admin | Username: admin | ||

Password: #$familab#$ | Password: #$familab#$ | ||

| − | |||

| − | 4) Click Print. | + | 4) Upload Gcode to Octoprint with 'upload' button under files menu. |

| + | |||

| + | 5) [[https://familab.org/wiki/File:05_SetHeat.PNG Preheat printhead]] under 'Temperature' tab. The Deltamaker does not have a heated bed. | ||

| + | |||

| + | 6) [[https://familab.org/wiki/File:06_CheckLayers.PNG Preview layers]] under 'Gcode Viewer' tab and check for any possible issues. | ||

| + | |||

| + | 7) Click 'Print' under state menu. | ||

| + | |||

| + | 8) Watch the magic happen... or take a nap. | ||

| + | |||

| + | 6) Print should pop off after print is complete. If it is extra adhered just pop it off with a flat paint scraper. Be careful not to damage the print bed. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | == The Ultimaker == | ||

| + | [[File:U01 Ultimaker.JPG|400px|thumb|left|Our Ultimaker]] | ||

| + | |||

| + | 1) Prep & slice 3D model. | ||

| + | |||

| + | 2) Turn on printer switch on back of machine. | ||

| + | |||

| + | 3) [[https://familab.org/wiki/File:03_Login.PNG Login to Octoprint]] on lab network. | ||

| + | URL: 192.168.10.62 (May not be accurate, please double check) | ||

| + | Username: familab | ||

| + | Password: #$familab#$ | ||

| + | |||

| + | 4) Upload Gcode to Octoprint with 'upload' button under files menu. | ||

| + | |||

| + | 5) [[https://familab.org/wiki/File:05_SetHeat.PNG Preheat printhead]] under 'Temperature' tab. The Deltamaker does not have a heated bed. | ||

| + | |||

| + | 6) [[https://familab.org/wiki/File:06_CheckLayers.PNG Preview layers]] under 'Gcode Viewer' tab and check for any possible issues. | ||

| + | |||

| + | 7) Click 'Print' under state menu. | ||

| + | |||

| + | 8) Watch the magic happen... or take a nap. | ||

| + | |||

| + | 6) Print should pop off after print is complete. If it is extra adhered just pop it off with a flat paint scraper. Be careful not to damage the print bed. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| − | |||

| − | + | == Troubleshooting == | |

| + | Simplify3d has a great [https://www.simplify3d.com/support/print-quality-troubleshooting/ print quality trouble shooting] guide for all of your failed print confusion! | ||

| + | |||

| + | |||

| + | ---- | ||

| + | |||

| + | The old 3D Printing page has been moved to [[3D Printing (archived)]] | ||

Latest revision as of 14:28, 26 January 2017

This page should be merged with 3D Printers . Please acquire all useful information from this page first but DO NOT DELETE.

Approved Lab Printer Filaments <--- Click here if you need to know which filament to buy for use on FamiLAB printers!

Contents

3D Editing Software

3D Slicing Software

-Simplify3d We have a lab license and this is the primary software used for our printers. Can be found on the right-hand FabLab printer.

Prepping Model for Slicing

Recommended File Type: OBJ or STL

Avoid 5+ sided faces

No manifold geometry or Lamina faces (faces sharing all edges)

Check scale and orientation! Z-up & Millimeters

Slice Model to Print

There are many model slicing softwares available. Each one gives you gCode but not all give you the same amount of control over your print settings. 3D Printing can be temperamental. From filament varieties, bed adhesion, and environmental changes many factors will effect the quality of your print. The widely preferred slicer at Familab is Simplify3d, which was crowd-funded in February 2016. Here is a quick start guide from Simplify3d!

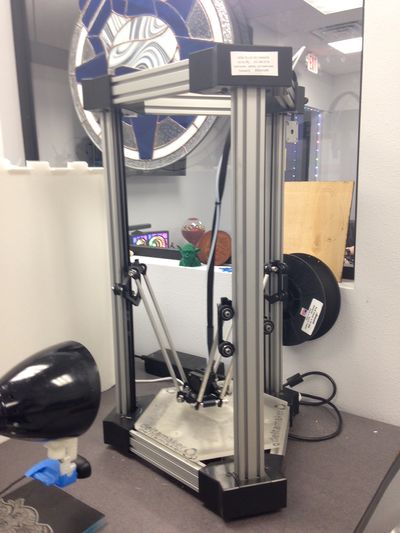

The DeltaMaker

1) Prep & slice 3D model.

2) Turn on printer switch on back of machine.

3) [Login to Octoprint] on lab network.

URL: deltamaker.familab.org Username: admin Password: #$familab#$

4) Upload Gcode to Octoprint with 'upload' button under files menu.

5) [Preheat printhead] under 'Temperature' tab. The Deltamaker does not have a heated bed.

6) [Preview layers] under 'Gcode Viewer' tab and check for any possible issues.

7) Click 'Print' under state menu.

8) Watch the magic happen... or take a nap.

6) Print should pop off after print is complete. If it is extra adhered just pop it off with a flat paint scraper. Be careful not to damage the print bed.

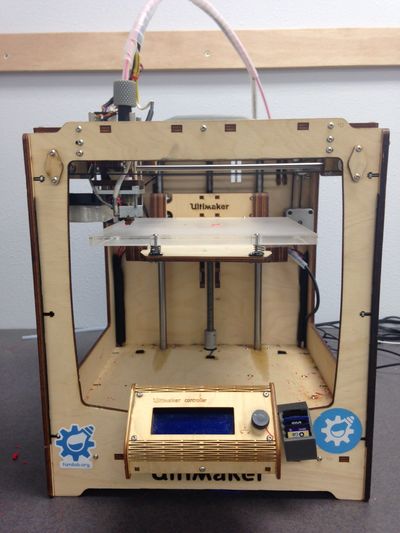

The Ultimaker

1) Prep & slice 3D model.

2) Turn on printer switch on back of machine.

3) [Login to Octoprint] on lab network.

URL: 192.168.10.62 (May not be accurate, please double check) Username: familab Password: #$familab#$

4) Upload Gcode to Octoprint with 'upload' button under files menu.

5) [Preheat printhead] under 'Temperature' tab. The Deltamaker does not have a heated bed.

6) [Preview layers] under 'Gcode Viewer' tab and check for any possible issues.

7) Click 'Print' under state menu.

8) Watch the magic happen... or take a nap.

6) Print should pop off after print is complete. If it is extra adhered just pop it off with a flat paint scraper. Be careful not to damage the print bed.

Troubleshooting

Simplify3d has a great print quality trouble shooting guide for all of your failed print confusion!

The old 3D Printing page has been moved to 3D Printing (archived)