Difference between revisions of "BreepBroop"

(Created page with "==Information== ===General=== The BreepBroop (nickname) is a standard [http://reprap.org/wiki/Mendel RepRap Mendel]. It's the original design, and was printed during the main bu...") |

(→General) |

||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | __NOTOC__ | ||

==Information== | ==Information== | ||

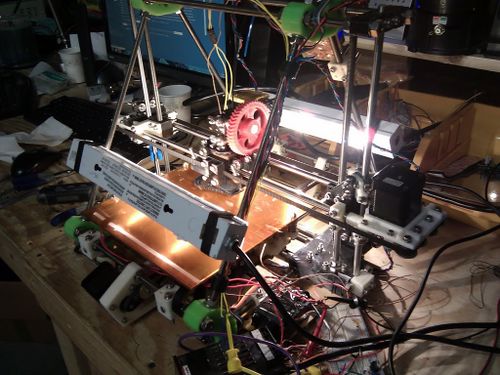

| − | + | [[File:BreepBroopLighting.jpg|thumb|500px|The BreepBroop in it's current state]] | |

===General=== | ===General=== | ||

| − | The BreepBroop (nickname) is a standard [http://reprap.org/wiki/Mendel RepRap Mendel]. It's the original design, and was printed during the main build rush after the Mendel came out. [[user:chorca|Chorca]] printed the parts on [[user: | + | The BreepBroop (nickname) is a standard [http://reprap.org/wiki/Mendel RepRap Mendel]. It's the original design, and was printed during the main build rush after the Mendel came out. [[user:chorca|Chorca]] printed the parts on [[user:Mack|Mack]]'s [[mackerbot|MakerBot]] over a period of about a month. It is all ABS aside from the frame vertexes which were purchased from the [http://forums.reprap.org/ RepRap Forums], from Joshua Updyke in particular. |

| − | This style of Mendel is rarely made anymore due to it's complexity. The much simpler [http://reprap.org/wiki/Prusa Prusa Mendel] is more commonly built, due to the large reduction of printed parts and hardware, and the simpler pulley and bearing systems used. [[ | + | This style of Mendel is rarely made anymore due to it's complexity. The much simpler [http://reprap.org/wiki/Prusa Prusa Mendel] is more commonly built, due to the large reduction of printed parts and hardware, and the simpler pulley and bearing systems used. [[Phineas|Digitalman2112's RepRap]] is a Prusa. |

===Electronics=== | ===Electronics=== | ||

| − | The BreepBroop originally used a [http://reprap.org/wiki/Generation_3_Electronics/Tech_Zone_Remix Techzone Gen3] electronics set, which needed a good amount of touch-up and had some issues. Chorca replaced | + | The BreepBroop originally used a [http://reprap.org/wiki/Generation_3_Electronics/Tech_Zone_Remix Techzone Gen3] electronics set, which needed a good amount of touch-up and had some issues. Chorca replaced this. |

| − | * | + | |

| − | + | * Currently using a RAMPS 1.2 board donated by [[user:digitalman2112|Digitalman2112]] | |

| − | * | + | * Bed heater is hooked into an [http://www.mouser.com/Search/ProductDetail.aspx?R=G3NE-210T-US-DC5virtualkey65300000virtualkey653-G3E-210T-US5 Omron 15A SSR], which is controlled by the DC heater output from the RAMPS. It modulates the SSR, and detects the temperature via a thermistor kapton-taped to the bed. |

| − | * | + | * With the RAMPS, the steppers are now all drive via the Pololus onboard the RAMPS board. |

| + | * Arduino MEGA on loan from [[user:digitalman2112|Digitalman2112]] | ||

===Mechanical=== | ===Mechanical=== | ||

| − | Most mechanical functions of the BreepBroop are according to the original build specifications. | + | Most mechanical functions of the BreepBroop are according to the original build specifications. A few modifications have been made: |

| − | * Using a Wade's extruder on the | + | * Using a Wade's extruder on the [http://www.thingiverse.com/thing:6278 OpenX carriage]. |

| − | + | * Hot end is a [http://www.lulzbot.com LulzBot] [http://www.lulzbot.com/en/hot-ends/1-budaschnozzle.html Budaschnozzle 1.0]. | |

| − | * Hot end is a [http://www. | + | * Bed has been modified to a 1/8" thick aluminum plate, using a 110v silicone mat heater from [http://www.mcmaster.com McMaster Carr] (Part number: 35765K482), controlled by an SSR. |

| − | * Bed has been modified to a 1/8" thick | ||

===Software=== | ===Software=== | ||

Chorca is currently using the following: | Chorca is currently using the following: | ||

| − | * Latest version of [ | + | * Latest version of [http://github.com/kliment/Sprinter Sprinter] firmware |

| − | * Host software is [ | + | * Host software is [http://github.com/kliment/Printrun Pronterface], using SFACT to interface with [http://fabmetheus.crsndoo.com/ Skeinforge] |

===Print Status=== | ===Print Status=== | ||

| − | The printer is | + | The printer is now working great. |

| + | |||

| + | After a rebuild with a new X carriage (which works very well), a new extruder ([http://www.thingiverse.com/thing:6713 Greg's Accessible Wade's]), the Lulzbot Budaschnozzle hot-end, a new bed, SSR for controlling it, and RAMPS kit with a Mega, things are beginning to come together. | ||

| + | I found that I had a little lash on my X axis after all that, and after some helpful advice in the #reprap chat on FreeNode, I found that Nophead's pulleys for the belts are NOT for XL-toothed belts, the kind I got from McMaster. They are for T5 belts, more common in Europe. I therefore printed a new pulley for the X axis, and the issue is gone! I need to do the same for the Y axis, which I somewhat dread because it means disassembling the bed once again (and having to re-level it). | ||

| + | |||

| + | However, the print quality right now is superb. Some of the issue I was having with printing seemed to be due to the white PLA I was using. Once I ran out of that and switched to green, many problems disappeared. I also noticed that I'm getting a grey plastic ooze coming out of the budaschnozzle in some spots, but that seems to have largely stopped as I've begun using green PLA. | ||

| + | |||

| + | I've printed a full set of frame vertexes with feet which I plan to install shortly (about the same time I replace the Y pulley) and I need to start getting the printer more self-contained (small onboard power supply, RAMPS enclosure, etc. | ||

==Current Work== | ==Current Work== | ||

===Electronics=== | ===Electronics=== | ||

| − | + | Swapped out all the electronics mess with a RAMPS [http://reprap.org/wiki/RAMPS RAMPS] platform. This integrates all components onto one shield for the Arduino MEGA, reducing footprint and making everything a lot easier to run. | |

| + | The following are current plans for work: | ||

| + | * Get a second SSR and set it up for the new heater block | ||

| + | * Incorporate a thermal fuse to prevent runaway of the heater | ||

| + | * Build a box for the RAMPS, and install a onboard power supply to help self-contain the unit | ||

| + | |||

| + | ===Mechanical=== | ||

| + | The following are current plans for work: | ||

| + | * <del>Replace copper bed with aluminum bed to lower stress on Y axis and prevent wobble</del> This is actually not due to the wobble of the bed, but due to using the wrong kind of pulley on my machine. The pulleys that Nophead has made and which are widely used on thingiverse are NOT the correct type for american XL-style belt tooth profiles. His are made for european T5 belts. The proper pulley for XL belt is [http://www.thingiverse.com/thing:7454 Here] | ||

Latest revision as of 00:49, 19 March 2012

Information

General

The BreepBroop (nickname) is a standard RepRap Mendel. It's the original design, and was printed during the main build rush after the Mendel came out. Chorca printed the parts on Mack's MakerBot over a period of about a month. It is all ABS aside from the frame vertexes which were purchased from the RepRap Forums, from Joshua Updyke in particular. This style of Mendel is rarely made anymore due to it's complexity. The much simpler Prusa Mendel is more commonly built, due to the large reduction of printed parts and hardware, and the simpler pulley and bearing systems used. Digitalman2112's RepRap is a Prusa.

Electronics

The BreepBroop originally used a Techzone Gen3 electronics set, which needed a good amount of touch-up and had some issues. Chorca replaced this.

- Currently using a RAMPS 1.2 board donated by Digitalman2112

- Bed heater is hooked into an Omron 15A SSR, which is controlled by the DC heater output from the RAMPS. It modulates the SSR, and detects the temperature via a thermistor kapton-taped to the bed.

- With the RAMPS, the steppers are now all drive via the Pololus onboard the RAMPS board.

- Arduino MEGA on loan from Digitalman2112

Mechanical

Most mechanical functions of the BreepBroop are according to the original build specifications. A few modifications have been made:

- Using a Wade's extruder on the OpenX carriage.

- Hot end is a LulzBot Budaschnozzle 1.0.

- Bed has been modified to a 1/8" thick aluminum plate, using a 110v silicone mat heater from McMaster Carr (Part number: 35765K482), controlled by an SSR.

Software

Chorca is currently using the following:

- Latest version of Sprinter firmware

- Host software is Pronterface, using SFACT to interface with Skeinforge

Print Status

The printer is now working great.

After a rebuild with a new X carriage (which works very well), a new extruder (Greg's Accessible Wade's), the Lulzbot Budaschnozzle hot-end, a new bed, SSR for controlling it, and RAMPS kit with a Mega, things are beginning to come together.

I found that I had a little lash on my X axis after all that, and after some helpful advice in the #reprap chat on FreeNode, I found that Nophead's pulleys for the belts are NOT for XL-toothed belts, the kind I got from McMaster. They are for T5 belts, more common in Europe. I therefore printed a new pulley for the X axis, and the issue is gone! I need to do the same for the Y axis, which I somewhat dread because it means disassembling the bed once again (and having to re-level it).

However, the print quality right now is superb. Some of the issue I was having with printing seemed to be due to the white PLA I was using. Once I ran out of that and switched to green, many problems disappeared. I also noticed that I'm getting a grey plastic ooze coming out of the budaschnozzle in some spots, but that seems to have largely stopped as I've begun using green PLA.

I've printed a full set of frame vertexes with feet which I plan to install shortly (about the same time I replace the Y pulley) and I need to start getting the printer more self-contained (small onboard power supply, RAMPS enclosure, etc.

Current Work

Electronics

Swapped out all the electronics mess with a RAMPS RAMPS platform. This integrates all components onto one shield for the Arduino MEGA, reducing footprint and making everything a lot easier to run. The following are current plans for work:

- Get a second SSR and set it up for the new heater block

- Incorporate a thermal fuse to prevent runaway of the heater

- Build a box for the RAMPS, and install a onboard power supply to help self-contain the unit

Mechanical

The following are current plans for work:

-

Replace copper bed with aluminum bed to lower stress on Y axis and prevent wobbleThis is actually not due to the wobble of the bed, but due to using the wrong kind of pulley on my machine. The pulleys that Nophead has made and which are widely used on thingiverse are NOT the correct type for american XL-style belt tooth profiles. His are made for european T5 belts. The proper pulley for XL belt is Here